BEIL0014_The Blister

|

Equipment:

|

|

|

Aluminum Sheet

|

Guillotine

|

|

Wood

Jigs

|

Metal

Clamps

|

|

Round

Nylon Headed Mallet

|

Corking

tools (different shapes)

|

|

Bolts

and Nuts

|

CNC

Router

|

|

MDF

|

Drill

|

Step one:

Creating the template to sandwich the metal

sheet, by using the CNC router. And drill four holes on close to the corners of

the template.

Step two:

Cut metal sheet into the size suit for the

template. Then place the sheets between the wood jig and clamp the figs

together tightly by bolts and nuts. And clamps whole set up on the benchtop by

metal clamps.

Step three:

Striking the metal sheet. Start from the

edge, using corking tools, where round headed mallet cannot reach.

Step four:

Hammer slowly close to the center. The closer

to the center, larger hammer should be used, to avoid less hammer mark. Hammer the

sheet follow the shape of the template. Slowly and patiently.

Step five:

Check the depth. I wanted to create a

blister with a depth slightly deeper than the thickness of template. If not

deep enough go back to step three.

|

| third check, still not deep enough |

|

| Perfect! |

Step six:

When the depth close to the thickness of

the template. Place anther jig beneath the setup to prevent hit the metal sheet

on the rough bench-top.

|

| Thank you for your sacrifice. |

|

| The depth is not enough close to the end of the tail, and shape is bad as well. |

Step seven:

Take out the metal sheet and check if the

surface is smooth, and if the edge is crispy can sharp. If not smooth go back

to step three or four. if the edge is nor clear enough, you can hammer the

sheet without the top jig, but remember to keep an eye on the flatness of the

unstriked part of the sheet.

|

| Still need further planishing. |

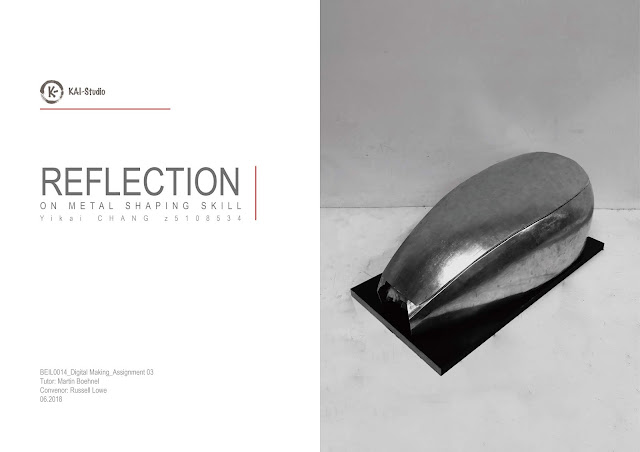

Final Product:

Comments

Post a Comment